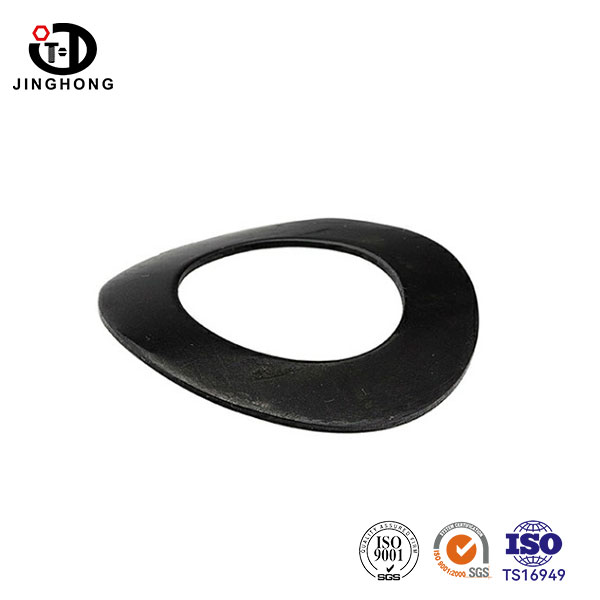

Curved Spring Washers

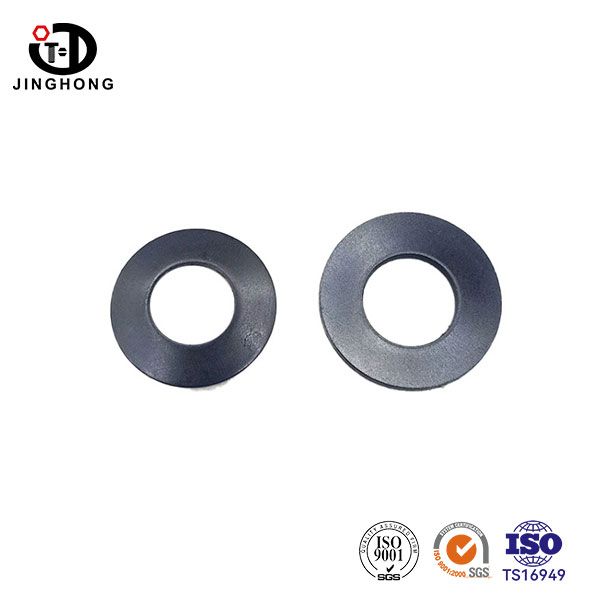

The primary purpose of high quality curved spring washers is to provide a spring-like action. When compressed, the conical shape allows them to deflect and absorb energy, acting as a resilient element that can return to its original shape after being compressed.

Send Inquiry

Curved spring washers have a conical or dish-like shape, with a larger diameter on one side and a smaller diameter on the other. This shape allows them to deflect and provide spring-like action when compressed. Curved spring washers are often made from materials such as carbon steel, stainless steel, or alloys with suitable spring properties. The material choice depends on the specific requirements of the application.

Product Specification

| Name | Curved spring Washers |

| Material | Stainless steel/alloy steel/carbon steel/brass/spring steel |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

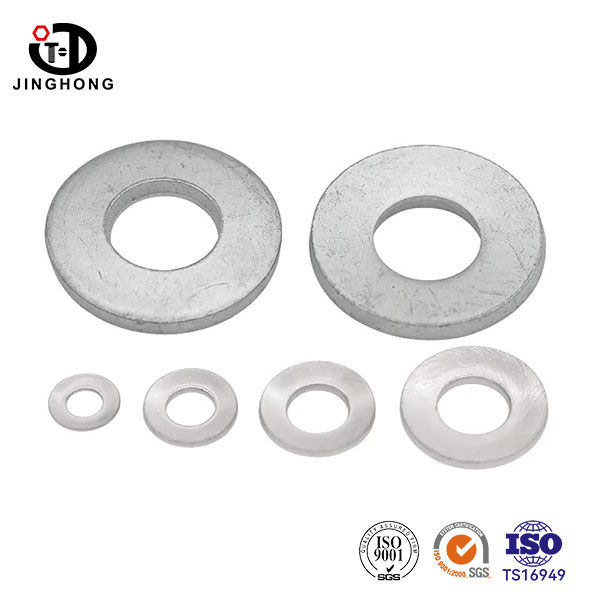

| Sizes | M2-M12 Metc |

| Finish | Zinc/Black/Natural/others |

| Price | 0.01usd/pcs-0.20usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

Curved spring washers are often used to preload bolts, nuts, or other fasteners. By placing a curved spring washer under the nut or bolt head, a constant tension force is maintained in the joint. This helps to prevent self-loosening of fasteners due to vibrations or dynamic loads.Curved spring washers can absorb and dampen vibrations and shocks in mechanical systems. This is particularly useful in applications where stability and reduced impact from dynamic forces are important, such as in automotive and machinery.Curved spring washers are effective in absorbing and distributing dynamic loads, making them valuable in situations where there are fluctuations in applied forces.They find applications in a wide range of industries, such as automotive, aerospace, construction, and machinery, where they are used in bolts, bearings, and other fastening and support systems.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.