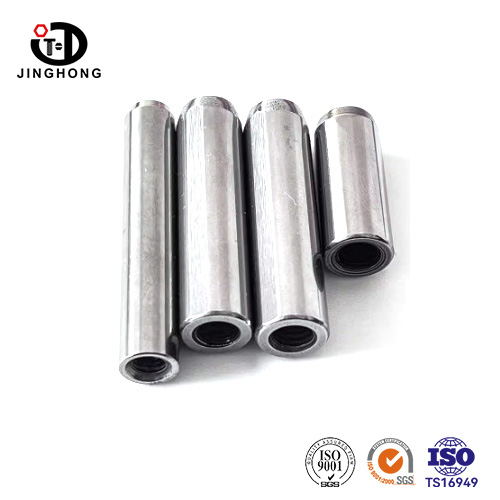

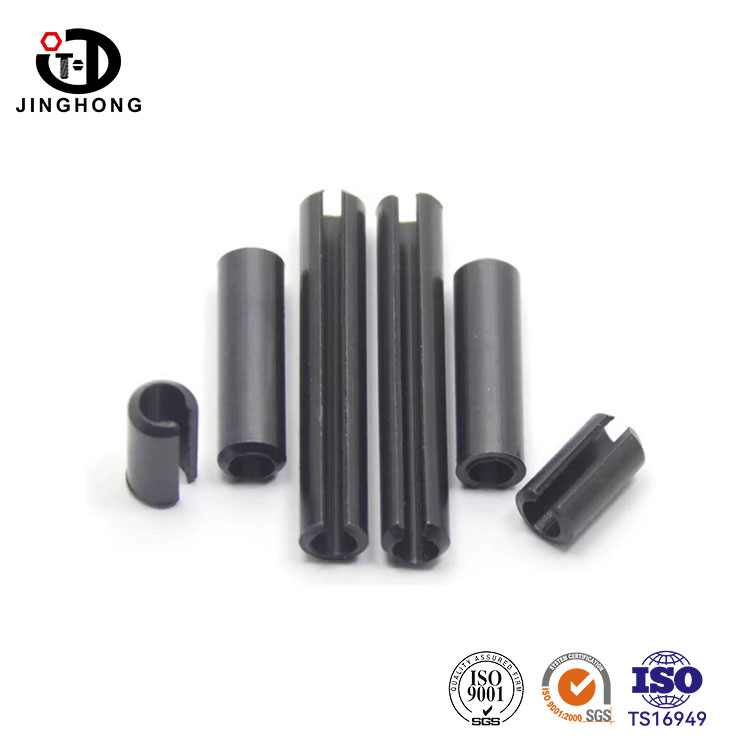

GCR15 Grooved Pin

GCR15 is a type of high-carbon chromium bearing steel, known for its durability, hardness, and wear resistance. The choice of this material suggests that the grooved pin would likely have good mechanical properties.The product features of a GCR15 Grooved Pin would likely depend on the specific design and intended use of the pin.

Send Inquiry

Jinghong fasteners has 20years more experience,if you need which one and what kind of material ,it’s up to your demand.If you have more specific questions or need more information you can contact us without any doubt.

| Name | GCR15 Grooved Pin |

| Material | Carbon |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

| Sizes | Φ6mm -Φ40mm Metc |

| Finish | Carbon /others |

| Price | 0.04usd/pcs-0.50usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

The material of a GCR15 Grooved Pin is typically GCR15 steel. GCR15 is a type of bearing steel known for its high carbon and chromium content.The pin would have one or more grooves along its length. The grooves may serve various purposes, such as facilitating easier insertion or removal, providing a location for retaining rings, or allowing for the attachment of other components.GCR15 Grooved Pins are likely to be manufactured with precision to meet specific dimensional requirements. This ensures consistency and reliability in their performance.GCR15 steel often contains chromium, which enhances its corrosion resistance. This feature would be important, especially if the grooved pin is used in applications where exposure to moisture or corrosive environments is a concern.Grooved pins are often used in various applications, including machinery, automotive, and industrial equipment. The design and features of the GCR15 Grooved Pin may make it versatile for different use cases.The surface finish of the grooved pin may be important for reducing friction and wear. It might have a smooth surface or a specific coating to enhance its performance.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.