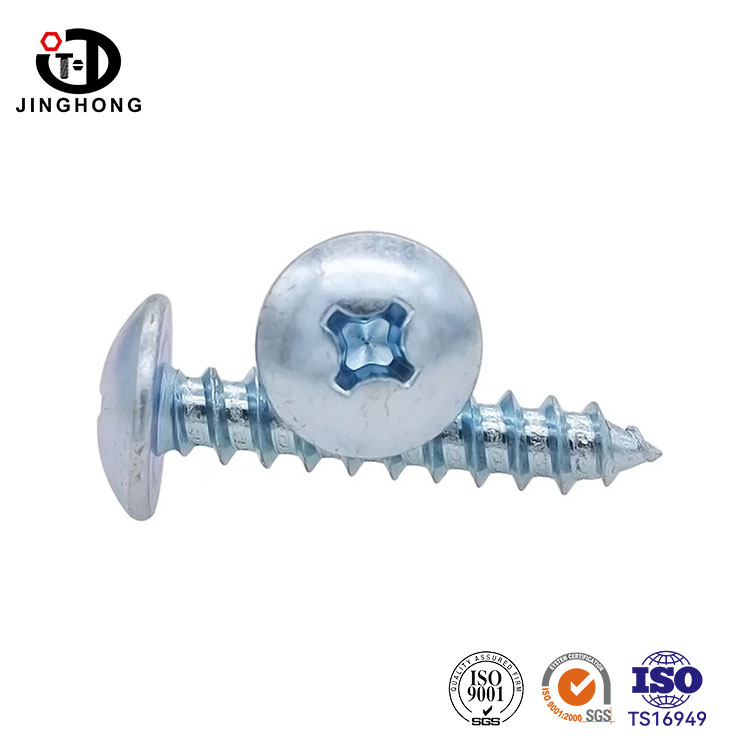

Hexagon Head Drilling Self-tapping Screw with Compound Washer

Jinghong manufacturer produces hexagonal head drilled self-tapping screws with composite washers, which are specialized fasteners for various construction and manufacturing applications. The design of the hexagonal head provides convenience when tightening with tools such as a wrench or screwdriver, improving installation efficiency. Composite gaskets typically consist of a metal backing and bonded rubber or neoprene gaskets for sealing and vibration resistance. It can effectively prevent the screw from loosening and leaking.

Send Inquiry

The fastener hexagonal head drilled self-tapping screws with composite washers supplied by Jinghong are made of stainless steel, carbon steel, etc., with a variety of options. The matching combination of hexagonal head drilling self-tapping screws and composite washers is easy to assemble, affordable and cost-effective.

Jinghong's standard parts are widely used in light industry, auto parts, mining machinery parts, household appliances, motors, papermaking machinery and other industries. We are a private enterprise in the industry, with a large scale and a complete range of standard and non-standard parts.

| Name | Hexagon Head Drilling Self-tapping Screw with Compound Washer |

| Material | Carbon Steel /304Stainless steel/410Stainless steel |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

| Sizes | ST4.8-ST6.3 Metc |

| Finish | Blue White Zinc/Yellow Zinc/others |

| Price | 0.04usd/pcs-0.50usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

Jinghong fastener hexagonal head self-drilling screw with composite washer have high quality, with easy installation, strong practicability, strong sealing, anti-vibration and other characteristics. They can drill themselves in materials such as metal and wood without the need for pre-drilling.

Before installation, the screw and washer should be checked to see if they are intact and replaced in time if damaged. Use a suitable tool for tightening and avoid damage caused by using a tool that is too large or too small. During the tightening process, attention should be paid to controlling the strength to avoid being too tight or too loose and causing the connection to be weak or damaged.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Patent certificate

Production workshop

Production workshop

Production workshop

Production workshop

Loading and transportation

Loading and transportation

Finished product workshop

Finished product workshop

CNC workshop

CNC workshop

Testing Office

Testing Office