Hexagon Round Head Chrome Plating Screw

The material used for Hexagon Round Head Chrome Plating Screw is usually high-strength steel or stainless steel, which has excellent corrosion resistance, wear resistance, and high temperature resistance, and can be used for a long time in harsh environments. The chrome plated surface treatment further enhances the anti-corrosion performance of the screws. The design of the semi-circular head not only makes the screw appear more rounded and smooth in appearance, but also greatly reduces interference with surrounding components during reassembly, making the installation process smoother and more efficient.

Send Inquiry

The chrome plating treatment of screws not only isolates direct contact between screws and corrosive substances, but also forms a hard protective layer on the surface of the screws, enhancing their wear resistance and scratch resistance. This dual protection mechanism allows the hexagonal oval head chrome plated screws to maintain their original performance and appearance in various environments.

Surface treatment can resist the erosion of most organic acids, sulfides, and alkalis, thus having high corrosion resistance, and can also improve the high temperature resistance and oxidation resistance of metal materials. Jinghong manufacturer precisely grasps the surface treatment of chrome plated screws to ensure that the screws meet the requirements of customers, providing customers with high-quality products, excellent services, and timely responses.

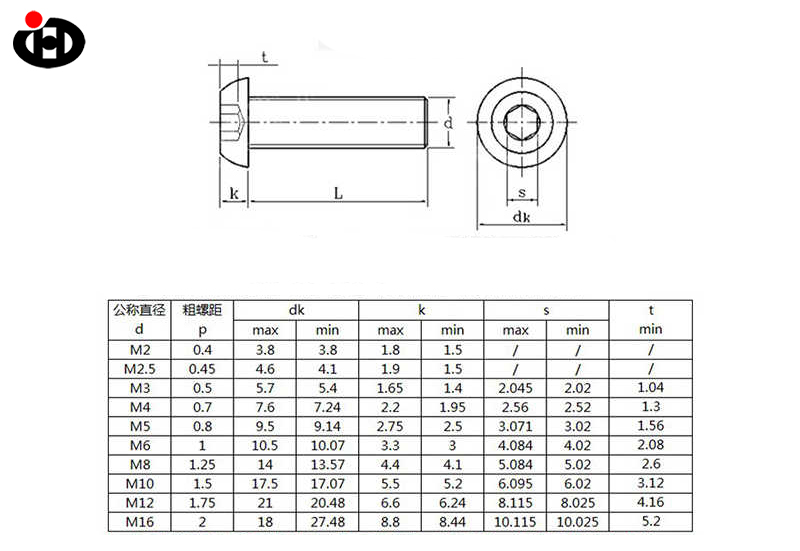

| Name | Hexagon Round Head Chrome Plating Screw |

| Material | Carbon Steel /304Stainless steel |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

| Sizes | M2-M16 |

| Finish | White Zinc/Nickel plated/Copper plated/Black/others |

| Price | 0.04usd/pcs-0.50usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

Jinghong factoy focuses on technological innovation and continuous improvement, constantly enhancing product performance and quality to meet the ever-changing needs of the market and customers. The assembly line can ensure consistency in size, quality, and appearance of products through standardized and automated process control. Accurate production processes and quality inspection systems can promptly detect and correct any problems in production, reducing the rate of defective products.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Patent certificate

Production workshop

Production workshop

Production workshop

Production workshop

CNC workshop

CNC workshop

Testing Office

Testing Office

Finished product workshop

Finished product workshop

Loading and transportation

Loading and transportation

Partners visit the factory