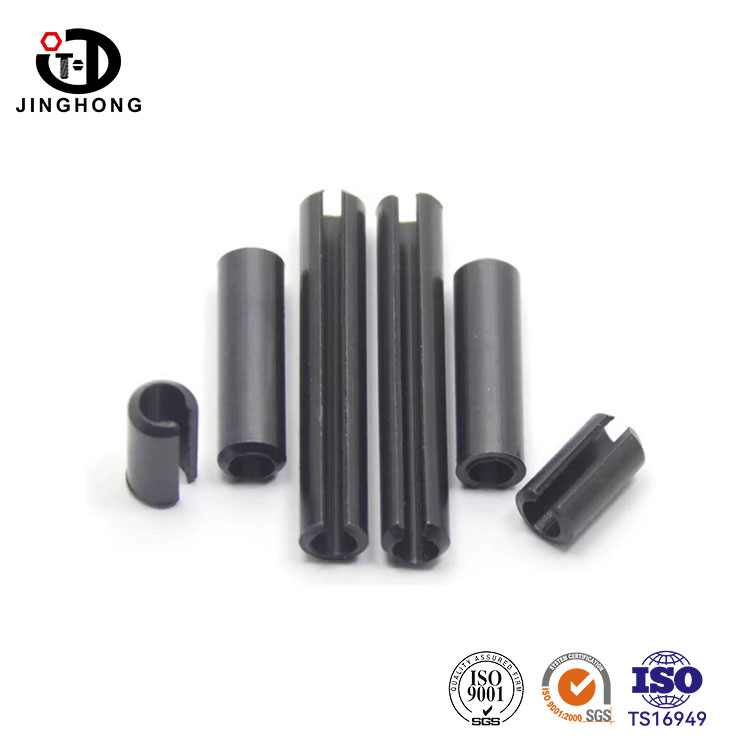

Stainless Steel Spring Pin with Teeth

The difference between Stainless Steel Spring Pin with Teeth and other elastic cylindrical pins is its unique toothed structure, which can increase stability and reduce the risk of loosening, elasticity is another important feature of this type of pin, this elasticity enables the product to produce appropriate elastic deformation under the action of external force, absorb and alleviate impact energy, protect connecting parts from damage, this elasticity is also easy to install and disassemble, and improve work efficiency.

Send Inquiry

Unlike traditional fasteners, which require tools and tedious steps, Stainless Steel Spring Pin with Teeth simplify these processes with their unique elastic design. When installing, you only need to gently push the pin into the prefabricated hole, and use its elastic deformation to quickly achieve locking, and when disassembling, you can easily pull it out by applying the appropriate reverse force, without additional tools or complicated operations.

The precision machined tooth profile of Stainless Steel Spring Pin with Teeth not only increases the contact area between the pin and the hole wall, effectively disperses the stress concentration, but also achieves a stronger effect through the occlusion between the teeth. The recyclability of stainless steel is in line with the current environmental protection concept, reducing resource waste and environmental pollution. At the same time, its good corrosion resistance reduces the additional energy consumption associated with replacing fasteners.

| Name | Stainless Steel Spring Pin with Teeth |

| Material | Stainless steel |

| Standards | GB,DIN, BSW, JIS, UNC, UNF, Non-standard, Customized Drawing |

| Thread | Metric Coarse, Metric Fine, UNC, UNF, BSW, BSF. |

| Sizes | Φ1-Φ20Metc |

| Finish | Stainless Steel /others |

| Price | 0.04usd/pcs-0.50usd/pcs |

| MOQ | Stardard item(Usually little hundred-little thousand)/determined if non-standard |

Product Feature

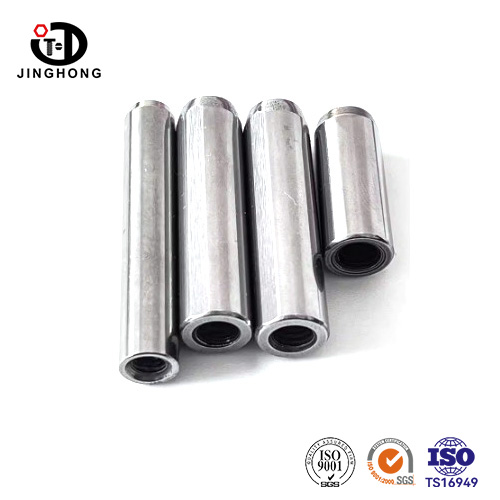

Jinghong manufacturer adopts advanced manufacturing technology and strict quality control system to ensure that the size of each pin meets the tolerance requirements. This precise tolerance control and dimensional stability not only ensures a perfect pin and hole match, but also improves assembly accuracy and efficiency, reducing the number of assembly problems caused by dimensional mismatches. It can also effectively affect the performance of equipment due to assembly errors, and improve the overall quality and reliability of the product.

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Patent certificate